Diy Acoustic Baffles

When people do the Diy Acoustic Baffles to the inside a building, not only the walls need to be treated, but also the ceiling. Many materials can be used for the acoustic ceiling,

Send Inquiry

PDF DownLoad

China Cheap Diy Acoustic Baffles Factory

"Control the standard by the details, show the energy by quality". Our enterprise has strived to establish a hugely efficient and stable staff members staff and explored an effective good quality control procedure for High reputation China Diy Acoustic Baffles for Meeting Room, Our experienced specialized group will be wholeheartedly at your support. We sincerely welcome you to check out our site and enterprise and send out us your inquiry.

High reputation China Acoustic Board, Wall Panels, We hope we can establish long-term cooperation with all of the customers, and hope we can improve competitiveness and achieve the win-win situation together with the customers. We sincerely welcome the customers from all over the world to contact us for anything you need to have!Welcome all customers both at home and abroad to visit our factory. We hope to have win-win business relationships with you, and create a better tomorrow.

1. Product Introduction of Diy acoustic baffles

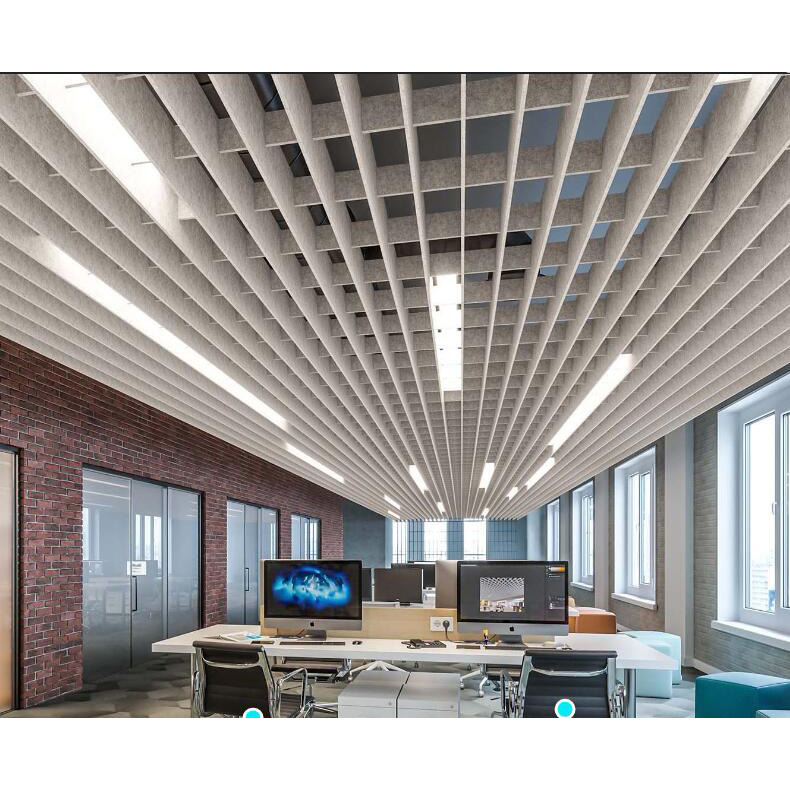

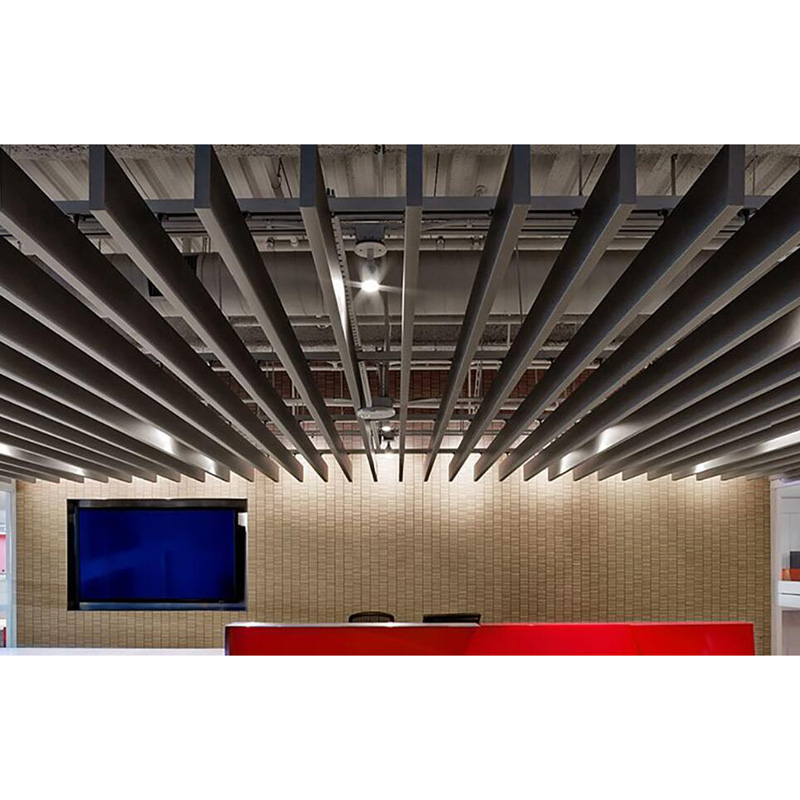

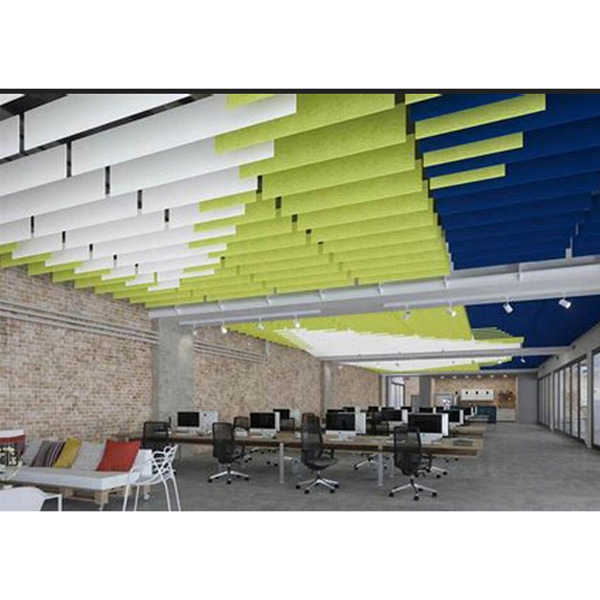

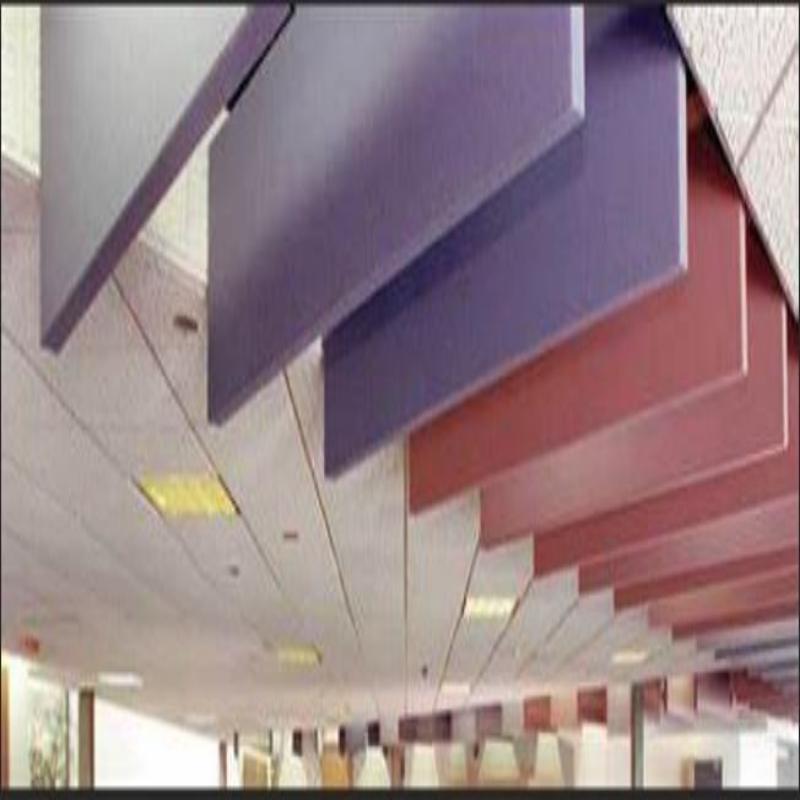

When people do the acoustic treatment to the inside a building, not only the walls need to be treated, but also the ceiling. Many materials can be used for the acoustic ceiling, such as mineral wool ceiling, fiberglass ceiling, wood ceiling, fiberglass ceiling. And they can also be in different forms, mostly in horizontal direction. In recently years, DIY acoustic baffles is getting more and more popular.

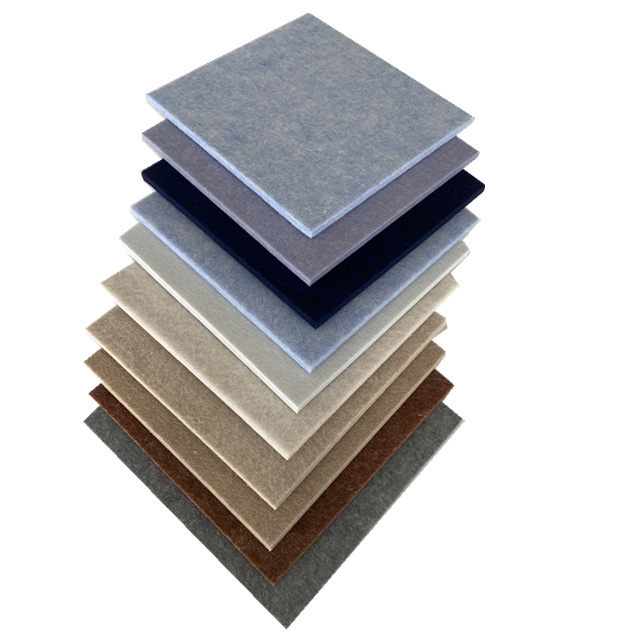

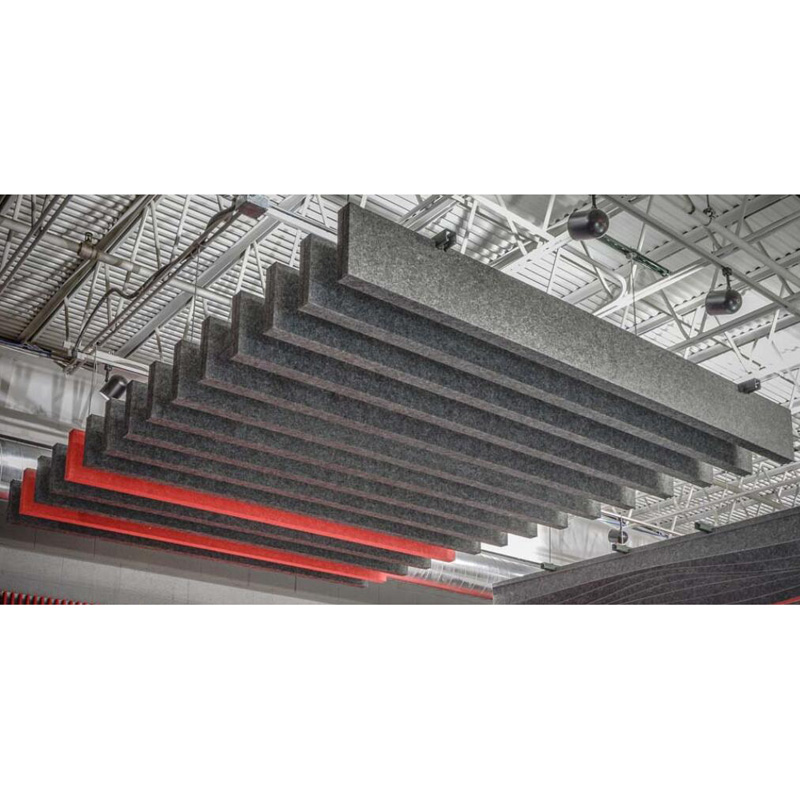

The diy acoustic baffles is a panel that is hanging on the ceiling vertically in a row. And they can be in different colors and shapes, it is made of dense and porous sound-absorbing board by hot pressing and needle punching of polyester fiber. Its full-frequency sound-absorbing function is very significant

2.Features of Diy acoustic baffles

Decorative: The baffles can be in different shapes and colors

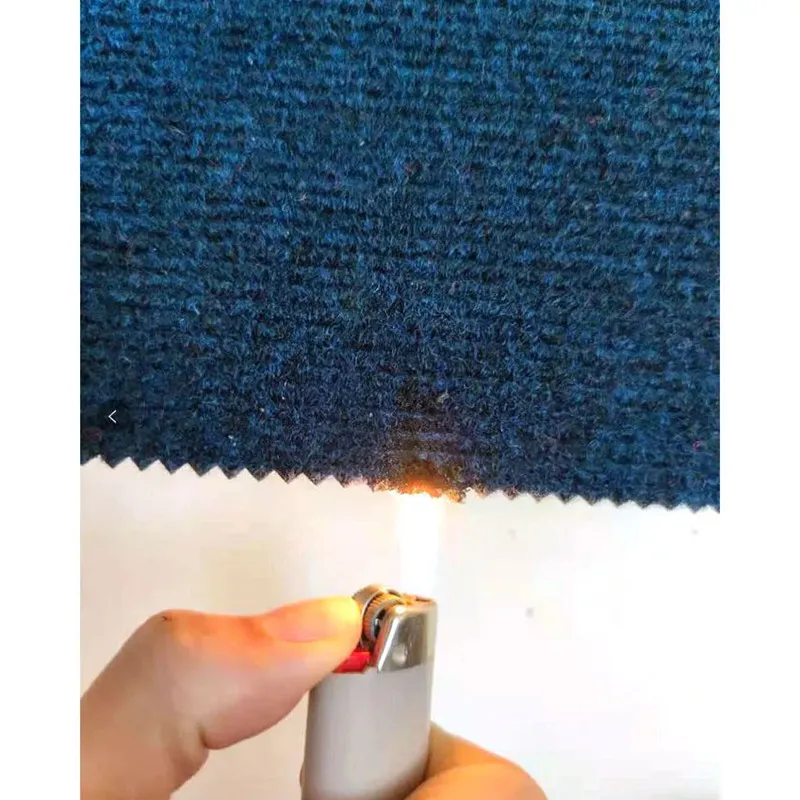

Flame-retardant: ASTM E84 Testing Class A Grade

Sound absorption and reverberation reduce

Easy to install

Environment friendly E0 Grade

Various Sizes available

3. Qualification of Diy acoustic baffles

We have 7 modern workshops and production line, with patent technology to make the stable products. Qdboss produces flame retardant Diy acoustic baffles, fabric wrapped fiberglass acoustic panel, fiberglass acoustic ceiling.

4 Packing of Diy acoustic baffles

We have standard carton packing for the full size polyester fiber panel (1220x2420*9mm), 10 pieces per carton, and the carton size is 2450x1250x105mm. Custom size cartons can also be made according to the sizes required by the client. And non-fumigation pallet can also be used upon request

5 How do the acoustic baffle work?

There are a large number of tiny interconnected pores inside the baffle. Acoustic waves can penetrate into the baffle along these pores, and frictional action with the material, converts sound energy into heat energy. After friction, the sound energy fades and less reverberation.

The sound wave propagates in the air and the air particles convert sound energy into heat energy due to vibration and friction. The phenomenon that the sound wave attenuates gradually with the increase of the propagation distance is called air absorption; when the sound wave enters the porous sound-absorbing material, due to the viscous resistance of the air, The vibration and friction between the air and the hole wall make a considerable part of the sound energy converted into heat energy and be absorbed, which is called material sound absorption.

6 Why Choose Qdboss Acoustic Diy acoustic baffles

1. Qdboss has ten years production experience for acoustic panels

2. We have thousands of projects to prove our good quality and service, especially in the cinema industry, Top 10 cinemas chains are using our cinema acoustic panel

3. 7 workshops and experienced workers to ensure the fast and production and delivery

4. 24/7 available for any question about acoustic panel

5. Full set of SGS testing report available for fire, thermal resistance, formaldehyde release

6. Qdboss is the supplier for several famous brand at home and abroad

7 How to Install Diy acoustic baffles

Simple process as below:

Cut the panel to required size – Install the hanging accessories on the baffle- mark the install point on the ceiling – insert the screw on the ceiling- hanging the baffle