Call Us

+86-15192680619

Email Us

info@qdboss.cn

What is Melt blown fabric?

2021-01-18

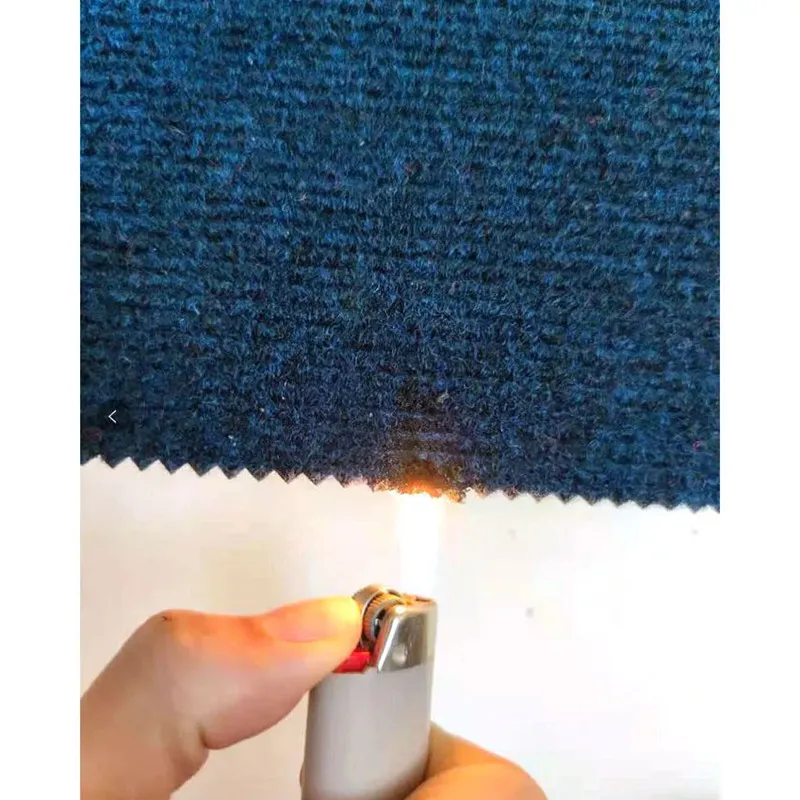

Melt blown fabric is the core material of masks, aliases, melt blown non-woven fabric, melt blown non-woven fabric. Melt blown fabric is to use high-speed hot air flow to draw the thin stream of polymer melt extruded from the orifice of the die, thereby forming ultra-fine fibers and collecting them on the net curtain or roller, and at the same time bonding themselves to become Melt-blown non-woven fabric.

Medical masks and N95 masks are composed of spunbond layer, meltblown layer and spunbond layer. Among them, the spunbond layer and meltblown layer are made of polypropylene PP material, and the fiber diameter can reach 1 to 5 microns. There are many voids, fluffy structure and good anti-wrinkle ability. The ultra-fine fibers with unique capillary structure increase the number and surface area of fibers per unit area, so that the meltblown fabric has good filterability, shielding, heat insulation and oil absorption.

Melt blown fabric can be used in air, liquid filter materials, isolation materials, absorbing materials, mask materials, thermal insulation materials, oil absorbing materials and wipe cloths.

Application range:

Application range:

(1) Medical and health cloths: surgical gowns, protective clothing, disinfection wraps, masks, diapers, sanitary napkins, etc.;

(2) Home decoration cloth: wall cloth, table cloth, bed sheet, bedspread, etc.;

(3) Garment cloth: lining, adhesive interlining, wadding, shaped cotton, various synthetic leather base cloth, etc.;

(4) Industrial cloth: filter material, insulating material, cement packaging bag, geotextile, covering cloth, etc.;

(5) Agricultural cloth: crop protection cloth, seedling raising cloth, irrigation cloth, insulation curtain, etc.;

(6) Others: space cotton, thermal insulation materials, linoleum, cigarette filters, tea bags, etc.

Medical masks and N95 masks are composed of spunbond layer, meltblown layer and spunbond layer. Among them, the spunbond layer and meltblown layer are made of polypropylene PP material, and the fiber diameter can reach 1 to 5 microns. There are many voids, fluffy structure and good anti-wrinkle ability. The ultra-fine fibers with unique capillary structure increase the number and surface area of fibers per unit area, so that the meltblown fabric has good filterability, shielding, heat insulation and oil absorption.

Melt blown fabric can be used in air, liquid filter materials, isolation materials, absorbing materials, mask materials, thermal insulation materials, oil absorbing materials and wipe cloths.

(1) Medical and health cloths: surgical gowns, protective clothing, disinfection wraps, masks, diapers, sanitary napkins, etc.;

(2) Home decoration cloth: wall cloth, table cloth, bed sheet, bedspread, etc.;

(3) Garment cloth: lining, adhesive interlining, wadding, shaped cotton, various synthetic leather base cloth, etc.;

(4) Industrial cloth: filter material, insulating material, cement packaging bag, geotextile, covering cloth, etc.;

(5) Agricultural cloth: crop protection cloth, seedling raising cloth, irrigation cloth, insulation curtain, etc.;

(6) Others: space cotton, thermal insulation materials, linoleum, cigarette filters, tea bags, etc.

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy