Application range of melt blown nonwoven fabric

2021-08-24

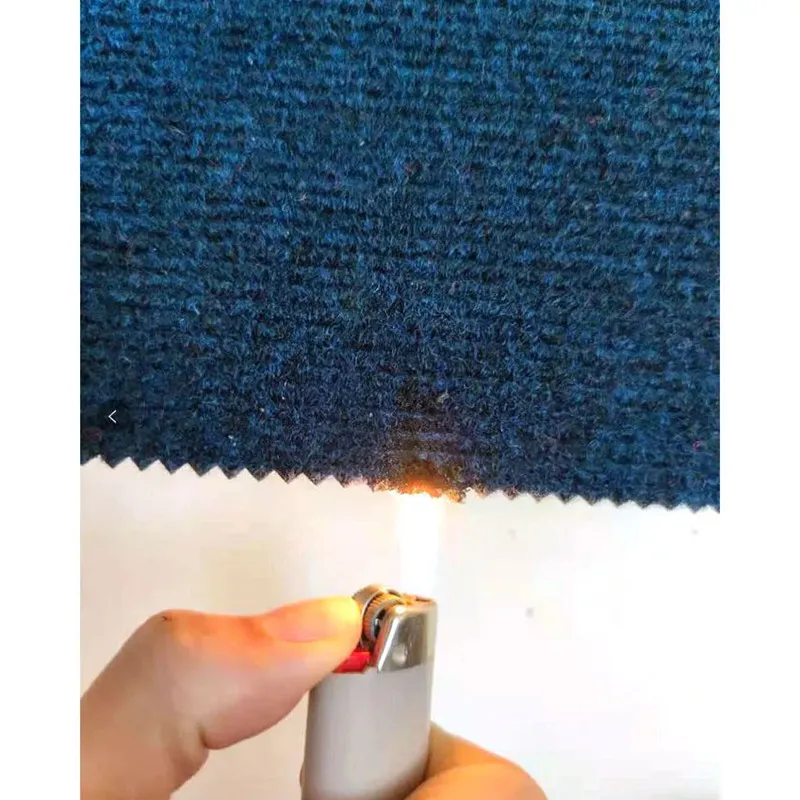

The filter material of the melt blown nonwoven fabric is randomly distributed and bonded together by polypropylene superfine fibers. The appearance is white, smooth and soft. The material fiber fineness is 0.5-1.0μm. The random distribution of fibers provides more space between the fibers. Thermal bonding opportunities, so that the melt blown gas filter material has a larger specific surface area, higher porosity (≥75%). After high-pressure electret filtration efficiency, the product has the characteristics of low resistance, high efficiency and high dust capacity.

(1) Medical and health cloths: surgical gowns, protective clothing, disinfection wraps, masks, diapers, women’s sanitary napkins, etc.;

(2) Home decoration cloth: wall cloth, table cloth, bed sheet, bedspread, etc.;

(3) Garment cloth: lining, adhesive lining, wadding, shaped cotton, various synthetic leather base cloth, etc.;

(4) Industrial cloth: filter material, insulating material, cement packaging bag, geotextile, covering cloth, etc.;

(5) Agricultural cloth: crop protection cloth, seedling raising cloth, irrigation cloth, thermal insulation curtain, etc.;

(6) Others: space cotton, thermal insulation materials, linoleum, cigarette filters, tea bags, etc.